| itacsa |

|

Installation and Operation: Installation and Operation:

To connect the valve Inlet and Outlet:

Connect the inlet and outlet in the direction of the arrow marked on the valve.

To connect DIN coil:

1. Remove the Philip screw from the plastic housing and unplug it from the DIN coil.

2. From the screw opening, push the terminal block out from the plastic housing.

|

|

|

| itacsa |

3. Note the 1, 2 and ground markings on underside of DIN enclosure.

4. For DC DIN Coil, Connect 1 to Positive, 2 to Negative.

5. For AC DIN Coil, connect 1 to HOT wire, 2 to Neutral wire, and if required connect

Note: Standard valves are supplied with continuous duty coils. The proper class of insulation for the

service is indicated on the coil. The coil temperature may become hot after being energized for extended

periods, but it is normal. Smoke or burning odor indicates excessive coil temperature and should

disconnect the power to the coil immediately.

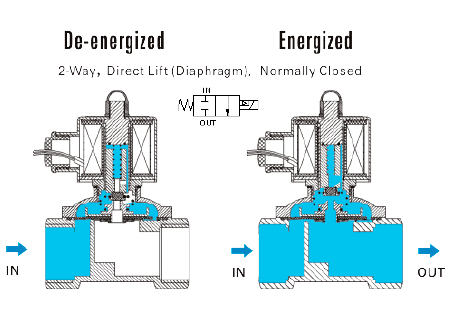

Operation: 2W160 series valve is a 2/2 Direct Lift Diaphragm Normally Closed, zero differential,

solenoid valve.

When the valve receives an electrical signal, a magnetic field is formed which attracts the plunger covering

the main orifice to lift off, causing system pressure to drop. As system pressure on the top of the diaphragm

is reduced, full system pressure on the other side of the diaphragm acts to lift the diaphragm

away from the main orifice, which allows media to flow through the valve. Since the bleed orifice is dimensionally

smaller than the pilot orifice, the system pressure cannot rebuild on the top of the diaphragm

as long as the pilot orifice remains open.

When the valve is de-energized, it releases its hold on the plunger. Then the plunger forced by the

spring drops and covers the main orifice. The system pressure builds up on the top of the diaphragm

through the bleed orifice, forcing the diaphragm down until it covers the main orifice and stops media

flow through the valve. |

|